Our Journey So Far:

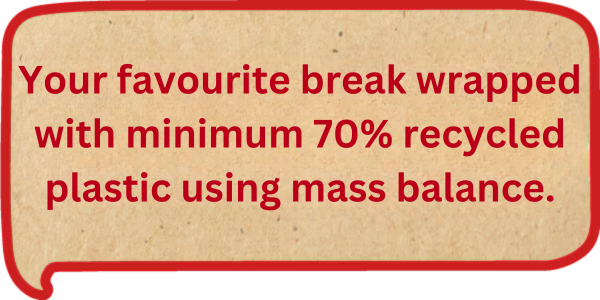

We started with our core Kit Kat 45g bar and block – initially 30% in 2022. Now we are moving to wrap our locally-made KitKat range of bars, blocks and share bags in a minimum of 70% recycled plastic packaging in 2025 (using mass balance).

We’re increasing the total amount of recycled plastic (using mass balance) we are sourcing for our wrappers.

We are rolling this out across locally made blocks, bars and share bags range. Come on the journey with us!

ISCC Certified

Our KITKATs are wrapped with a minimum 70% recycled plastic that are ISCC certified.

Founded in 2010 through a multi-stakeholder initiative, the International Sustainability and Carbon Certification (ISCC) is a globally applicable and leading certification system designed to enhance traceable, sustainable supply chains. ISCC certifications are widely recognised and cover recycled carbon-based materials and other categories including sustainable agricultural biomass, biogenic wastes and residues and non-biological renewable materials. The development and implementation of different certification standards is ISCC’s tool to promote its mission to bring more traceability into global markets and supply chains.

The ISCC PLUS standard, in particular, supports the transition to a circular economy and bioeconomy. This voluntary certification standard validates the sustainability characteristics of alternative feedstocks throughout the entire supply chain, from origin to end consumer.

What is mass balance?

The mass balance approach is a chain of custody method used to trace the flow of alternative feedstocks through complex value chains. During the production process, the certified feedstocks are mixed with conventional materials and the products become physically indistinguishable from those made solely from conventional feedstocks.

By using the mass balance system, companies can document and track the exact amount of alternative feedstocks used, ensuring that the quantity of alternative feedstocks allocated to the product matches the quantity sourced at the start of the production. One of the major advantages of the mass balance approach is its flexibility: companies can gradually increase the share of alternative feedstocks in the production process without altering the existing infrastructure.

Working towards a waste free future

Our vision is that none of our packaging, including plastics, ends up in landfill, in oceans, lakes and rivers. We are working hard to deliver on this and help achieve a waste-free future.